Products

1.PEM Stack

1. SOLARWAY’s Small PEM Stacks

Product name : SWPS-P10SC

PEM Water Electrolyzer Stack – 10 cells

-Description

The development of high-efficiency platinum electrodes based on the core technology reduces the system production cost and generates hydrogen through the high-yielding rate per input power, and this technology has a long-life cycle activating over 30,000 hours (for platinum-based electrodes). The estimated lifetime for the PEM electrolyzer stack (or individual cells present in the stack hardware) is 30,000 operational hours. This PEM electrolyzer stack requires a solution of distilled water for its efficient operation.

Hydrogen generated from the water electrolyzer is used as the energy storage medium for HESS (Hydrogen Energy Storage System). The water electrolyzer can be even powered by renewable energy such as solar, wind-power, tidal, night-time electricity, and surplus power energy. When needed, hydrogen is converted to electricity by the fuel cell.

Applications:

- Redundant renewable energy transformation and storage

• Lab experiment and teaching

• Laboratory analytic instrument

• Hydrogen healthy care industrial

• Hydrogen beauty industrial

• Fuel for special field

• Hydrogen supply for fuel cell

• Other pure H2 application field

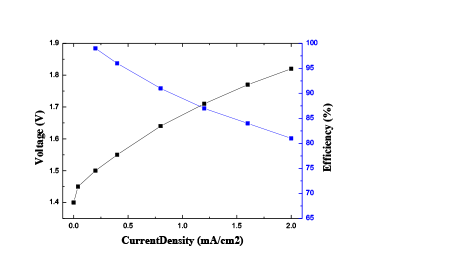

-technical specifications

- Size: 100 X 100 X 81

- Material: Anodizing Al, Ti

- Number of Cell: 10

- Electrode Material : Pt, IrO2

- Membrane: nafion 117

- Applied voltage range 17~20V

- Current range: 0~50A

- Operating temperature: 15 ~85℃

- Solution : distilled water

- Active Area per Cell: 25cm2

- H2 Flow rate: 7l/min

- O2 Flow rate : 1.85l/min

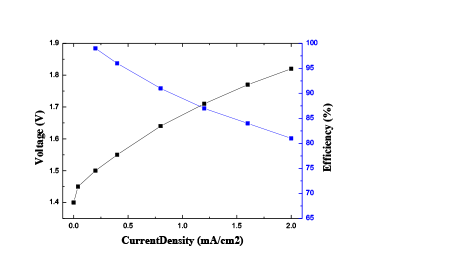

Electrolyzer Cell Representative IV Curve

Product name : LBE-P12SC

PEM Water Electrolyzer Stack – 12cell

-Description

The development of high-efficiency platinum electrodes based on the core technology reduces the system production cost and generates hydrogen through the high-yielding rate per input power, and this technology has a long-life cycle activating over 30,000 hours (for platinum-based electrodes). The estimated lifetime for the PEM electrolyzer stack (or individual cells present in the stack hardware) is 30,000 operational hours. This PEM electrolyzer stack requires a solution of distilled water for its efficient operation.

Hydrogen generated from the water electrolyzer is used as the energy storage medium for HESS (Hydrogen Energy Storage System). The water electrolyzer can be even powered by renewable energy such as solar, wind-power, tidal, night-time electricity, and surplus power energy. When needed, hydrogen is converted to electricity by the fuel cell.

Applications:

- Redundant renewable energy transformation and storage

• Lab experiment and teaching

• Laboratory analytic instrument

• Hydrogen healthy care industrial

• Hydrogen beauty industrial

• Fuel for special field

• Hydrogen supply for fuel cell

• Other pure H2 application field

-Technical specifications

- Size: 100 X 100 X 93

- Material: Anodizing Al, Ti

- Number of Cell: 12

- Electrode Material : Pt, IrO2

- Membrane: nafion 117

- Applied voltage range 4~24V

- Current range: 0~50A

- Operating temperature: 15 ~85℃

- Solution : distilled water

- Active Area per Cell: 25cm2

- H2 Flow rate: 4l/min

- O2 Flow rate : 2.2l/min

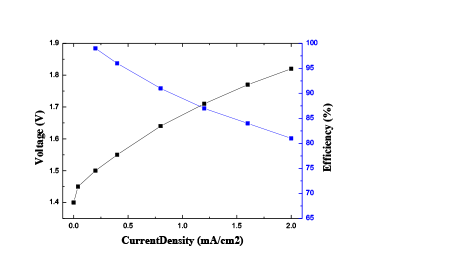

Electrolyzer Cell Representative IV Curve

Product name : LBE-P24SC

PEM Water Electrolyzer Stack – 24cell

-Description

The development of high-efficiency platinum electrodes based on the core technology reduces the system production cost and generates hydrogen through the high-yielding rate per input power, and this technology has a long-life cycle activating over 30,000 hours (for platinum-based electrodes). The estimated lifetime for the PEM electrolyzer stack (or individual cells present in the stack hardware) is 30,000 operational hours. This PEM electrolyzer stack requires a solution of distilled water for its efficient operation.

Hydrogen generated from the water electrolyzer is used as the energy storage medium for HESS (Hydrogen Energy Storage System). The water electrolyzer can be even powered by renewable energy such as solar, wind-power, tidal, night-time electricity, and surplus power energy. When needed, hydrogen is converted to electricity by the fuel cell.

Applications:

- Redundant renewable energy transformation and storage

• Lab experiment and teaching

• Laboratory analytic instrument

• Hydrogen healthy care industrial

• Hydrogen beauty industrial

• Fuel for special field

• Hydrogen supply for fuel cell

• Other pure H2 application field

-Technical specifications

- Size: 100 X 100 X 153

- Material: Anodizing Al, Ti

- Number of Cell: 24

- Electrode Material : Pt, IrO2

- Membrane: nafion 117

- Applied voltage range 8~48V

- Current range: 0~50A

- Operating temperature: 15 ~85℃

- Solution : distilled water

- Active Area per Cell: 25cm2

- H2 Flow rate: 8l/min

- O2 Flow rate : 4.4l/min

Electrolyzer Cell Representative IV Curve

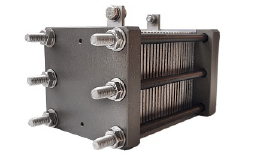

Big PEM Stack

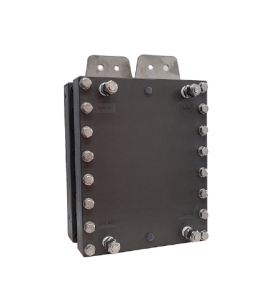

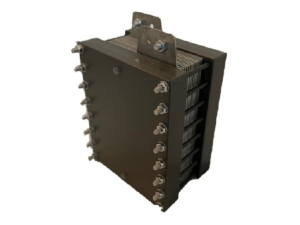

Product name – SWPS-P6C

PEM Water Electrolyzer Stack – 6 cells

-Description

The development of high-efficiency platinum and IrO2 electrodes with a PFSA membrane such as Nafion 117 as the core technology for this PEM water electrolyzer stack reduces the system production cost and generates hydrogen through the high-yielding rate per input power, and this technology has a long-life cycle over 30,000 hours (for platinum-based electrodes). The estimated lifetime for the PEM electrolyzer stack (or individual cells present in the stack hardware) is 30,000 operational hours. The lifetime of any kind of PEM water electrolyzer is a function of multiple aspects such as water source quality, number of start-up and shut-down cycles, operational voltage and current, etc. and depending on those factors, one may or may not achieve the stated lifetime hours. This PEM electrolyzer stack requires 16-18 Megaohms quality distilled water for its efficient operation.

Hydrogen generated from the water electrolyzer is used as the energy storage medium for HESS (Hydrogen Energy Storage System). The water electrolyzer can be even powered by renewable energy such as solar, wind-power, tidal, night-time electricity, and surplus power energy. When needed, hydrogen is converted to electricity by the fuel cell.

Applications:

- Redundant renewable energy transformation and storage

- Lab experiment and teaching

- Laboratory analytic instrument

- Hydrogen healthy care industrial

- Hydrogen beauty industrial

- Fuel for special field

- Hydrogen supply for fuel cell

- Other pure H2 application field

-Technical specifications

Size : 214 X 265 X 117mm

Material : Anodized Al as endplates and Ti for bipolar plates and diffusion layers

Electrode material : Ti for cathode and IrO2 for anode

Membrane : Nafion 117

Apply voltage range : 1.6V ~ 2.0V per a cell

Current : 0~540 (Max) Amps

Temperature : 15 ~ 80 deg C

Water : deionized water or distilled water

Active area : 270 cm^2

H2 flow : up to 1450l/h

O2 flow : up to 725/h

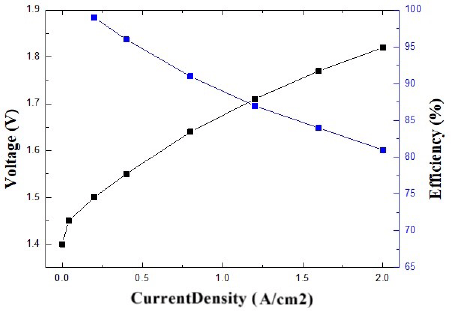

Electrolyzer Cell Representative IV Curve:

The following graph provides an example performance curve for this product.

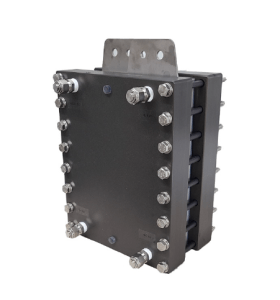

Product name – SWPS-P12C

PEM Water Electrolyzer Stack – 12 cells

-Description

The development of high-efficiency platinum and IrO2 electrodes with a PFSA membrane such as Nafion 117 as the core technology for this PEM water electrolyzer stack reduces the system production cost and generates hydrogen through the high-yielding rate per input power, and this technology has a long-life cycle over 30,000 hours (for platinum-based electrodes). The estimated lifetime for the PEM electrolyzer stack (or individual cells present in the stack hardware) is 30,000 operational hours. The lifetime of any kind of PEM water electrolyzer is a function of multiple aspects such as water source quality, number of start-up and shut-down cycles, operational voltage and current, etc. and depending on those factors, one may or may not achieve the stated lifetime hours. This PEM electrolyzer stack requires 16-18 Megaohms quality distilled water for its efficient operation.

Hydrogen generated from the water electrolyzer is used as the energy storage medium for HESS (Hydrogen Energy Storage System). The water electrolyzer can be even powered by renewable energy such as solar, wind-power, tidal, night-time electricity, and surplus power energy. When needed, hydrogen is converted to electricity by the fuel cell.

Applications:

- Redundant renewable energy transformation and storage

- Lab experiment and teaching

- Laboratory analytic instrument

- Hydrogen healthy care industrial

- Hydrogen beauty industrial

- Fuel for special field

- Hydrogen supply for fuel cell

- Other pure H2 application field

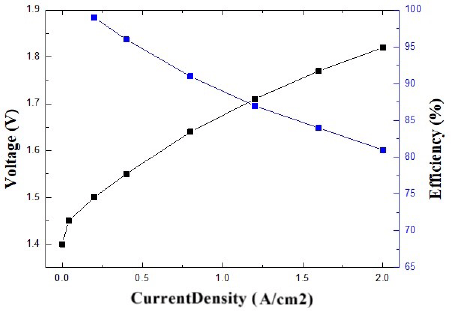

-Technical specifications

Size : 214 X 265 X 150mm

Material : Anodized Al as endplates and Ti for bipolar plates and diffusion layers

Electrode material : Ti for cathode and IrO2 for anode

Membrane : Nafion 117

Apply voltage range : 1.6V ~ 2.0V per a cell

Current : 0~540 (Max) Amps

Temperature : 15 ~ 80 deg C

Water : deionized water or distilled water

Active area : 270 cm^2

H2 flow : up to 2900l/h

O2 flow : up to 1450/h

Electrolyzer Cell Representative IV Curve:

The following graph provides an example performance curve for this product.

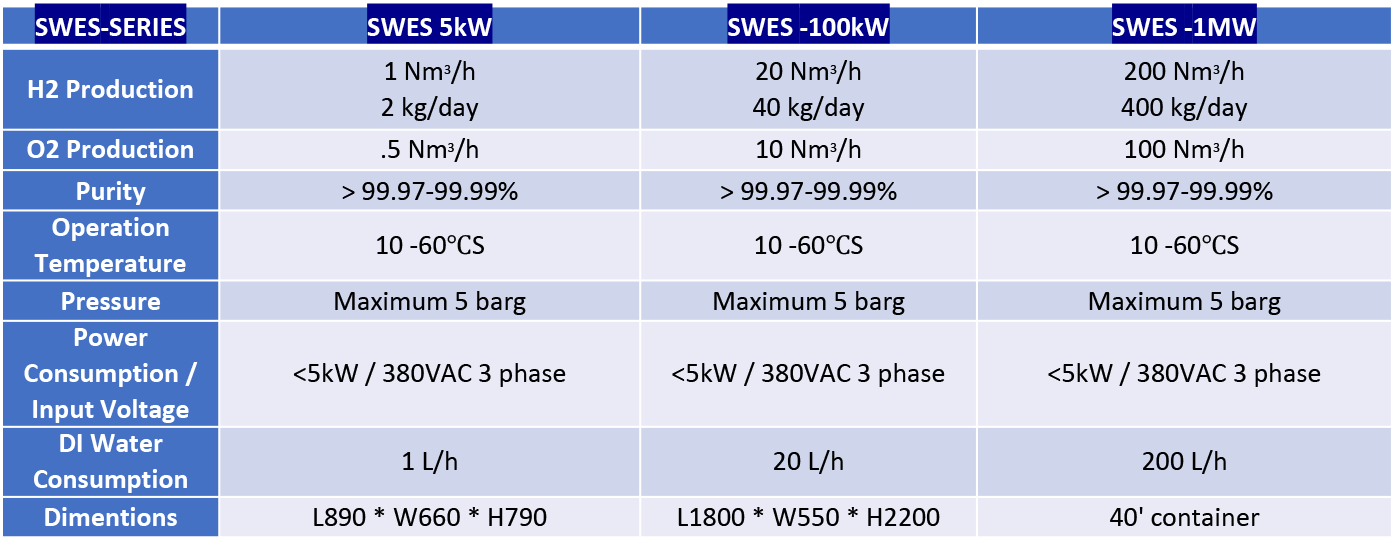

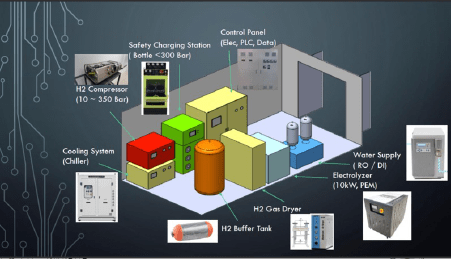

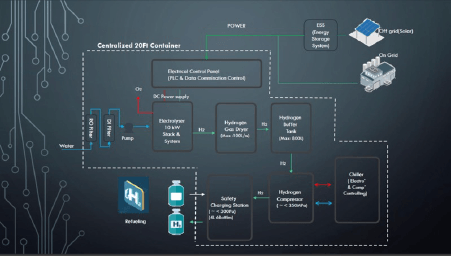

2. SOLARWAY’s PEM Electolyzer Solution

SOLARWAY with modularized PEM stack technology manufactures electrolyzers from 5kW to 1MW scale. Instead of a large single cell stack design, we utilize multiple units of modularized stacks in order to manage each stacks individually. For the 1MW electrolyzer, we use 5 of 100kW single cell stacks and if one stack has a problem the rest of four stacks will be still running. In another word, the electrolyzer will never shut down and one bad stack can be simply replaced. For a 1MW electrolyzer, it is combined with containerized and compact design, that can be installed outdoors in any ambient temperature.

SWES 10kW 3D-modeling picture

SWES 10kW actual picture

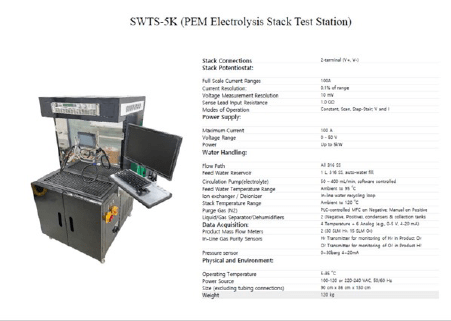

3. HydrogenWay’s PEM stack test station

SOLARWAY’s R&D center developed PEM stack test station to test our own PEM stacks. It is equipped with Powerful analysis package with real time analysis, log of the data, DC polarization curve, membrane cyclic voltammetry with negative volt capability. It can be operated up to 30 bar max working pressure and optional Integral Electrochemical Impedance Spectroscopy (EIS) measuring system to directly drive the stack.

- Power range up to 100 kW

- Temperature ranges up to 100 °C

- PLC controlled with multi-level alarm management

- Flexible thermal and electrical load management

- Precise back pressure control

- Dynamic temperature and pressure management

- Fully automated, unattended operation

- Integrated impedance spectroscopy (option)

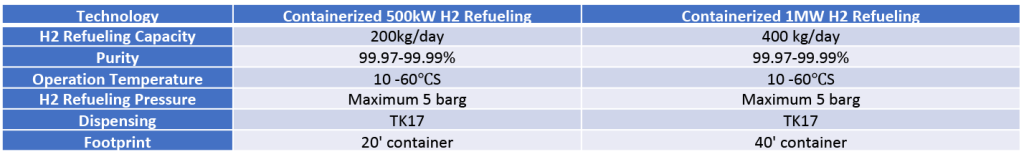

4. SOLARWAY’s Refueling Station Solution

SOLARWAY offers a wide range of hydrogen stations., equipped with technical and digital innovation which generate a few kg to hundred of thousand kg of hydrogen at 350 and 700 bar. Our modular and compact designed dual charging stations enable our customers to refuel FCV such as Hyundai’s NEXO at 700 bar and also to refuel Fuel cell buses and commercial trucks at 350 bar in one system.

By integrating our PEM electrolyzer, compressor, storage and dispenser together for any FCV applications, SOLARWAY enables our customer to produce, on-site and on-demand hydrogen and it can be installed anywhere with any weather conditions. We also manufacture portable stations which can be move around from places to places.

Example of a concept drawing for small-scale refueling station for fuel cell bicycles.

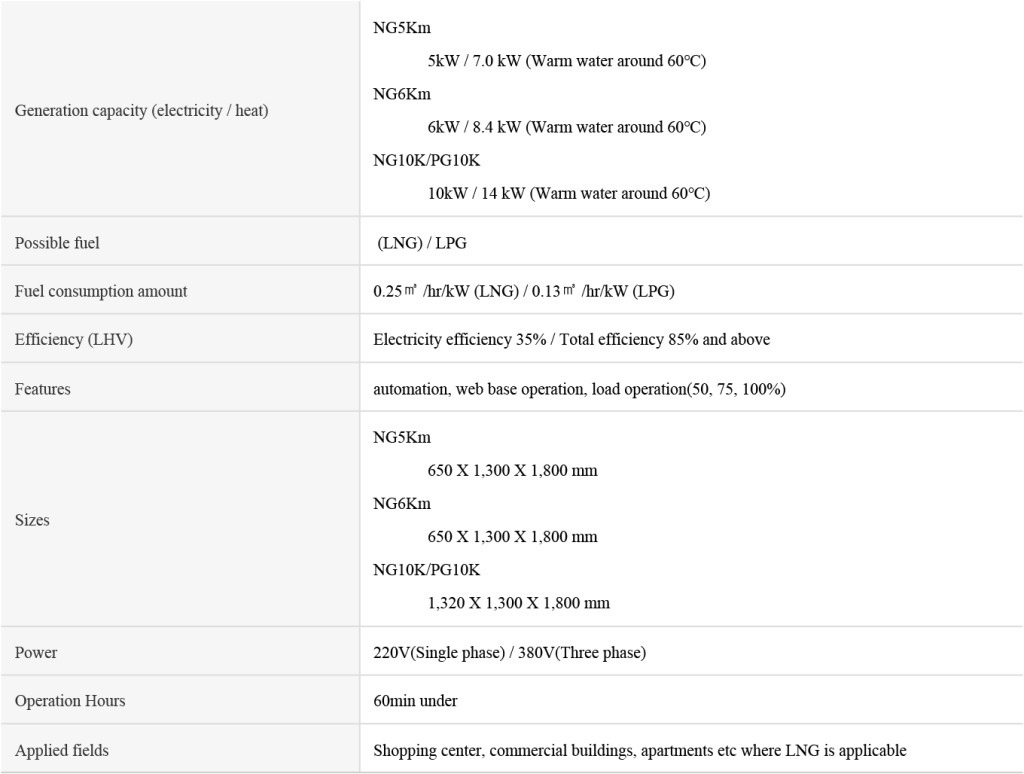

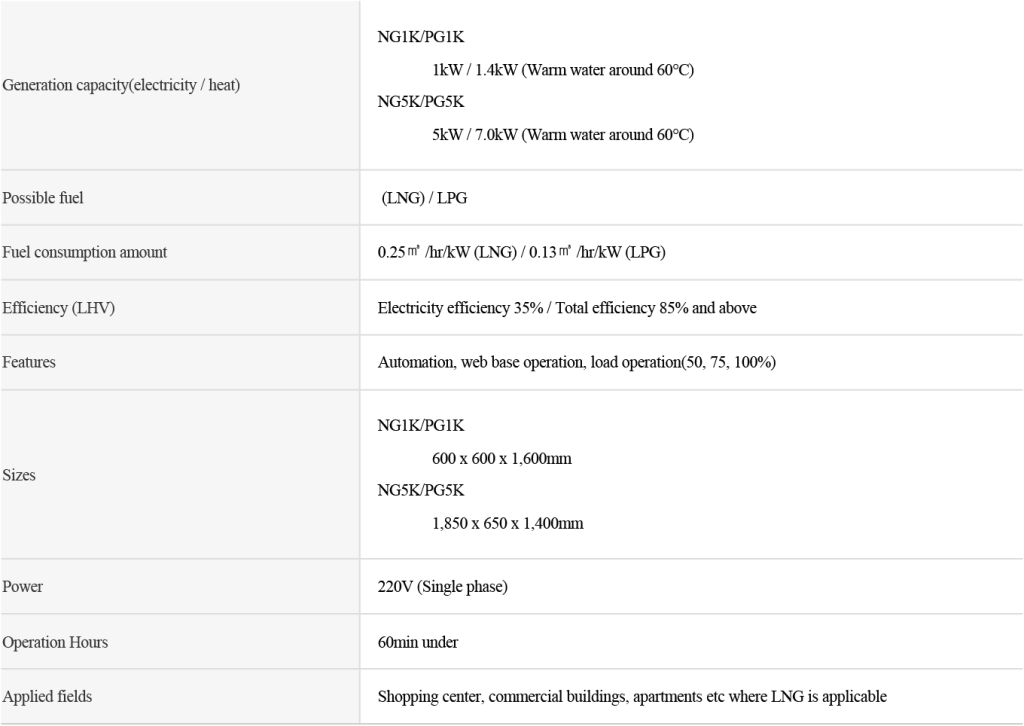

5. SOLARWAY’s Fuel Cell Solution

SOLARWAY proudly represent our partner S-Fuelcell Korea. We are an official authorized international distributor of S-Fuelcell’s products.

Products

Building generation purpose

5~10kW scale fuel cell system

ecogener NG5Km ~ NG10K/PG10K

1~5kW scale fuel cell system

ecogener NG1K~NG5K / PG1K~PG5K

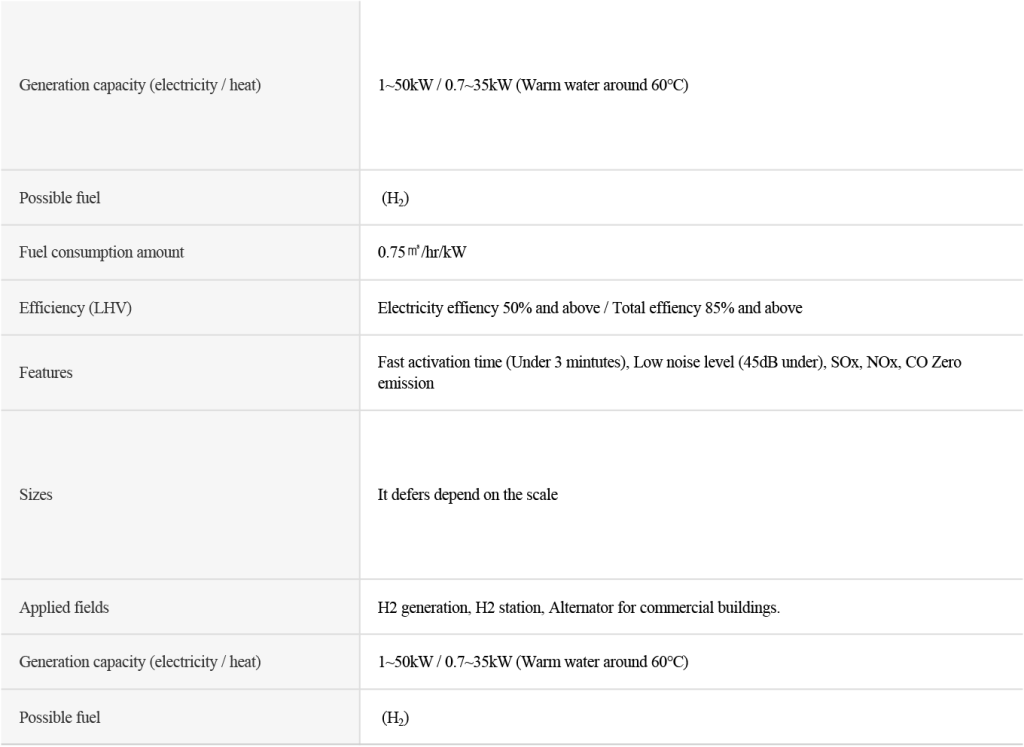

1~50kW scale H2 generation system

ecogener HG1K~HG50K

Line up generation purpose

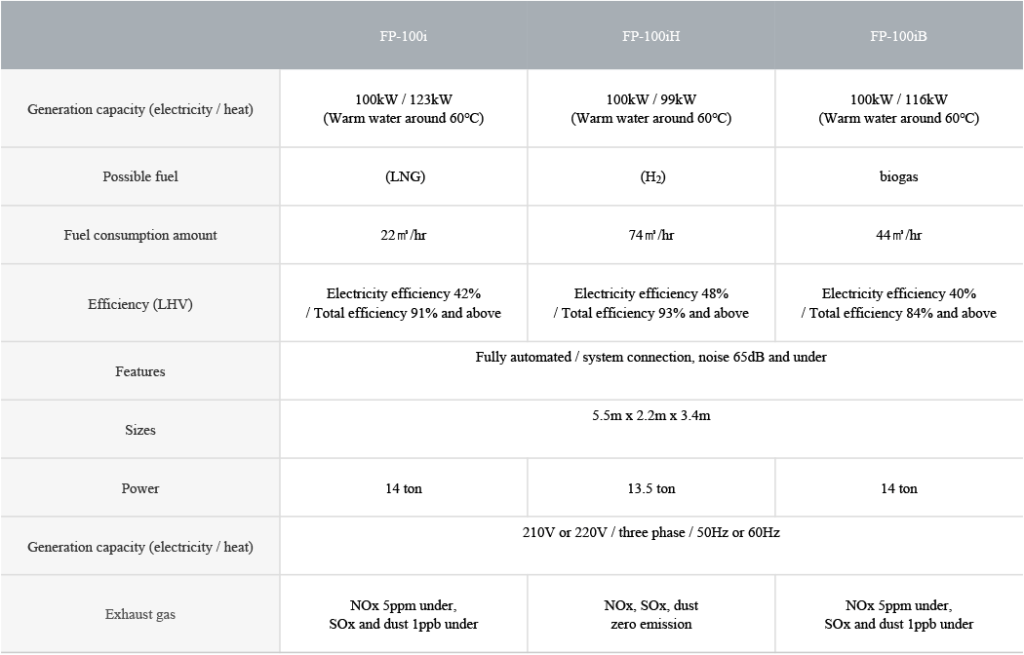

System specification